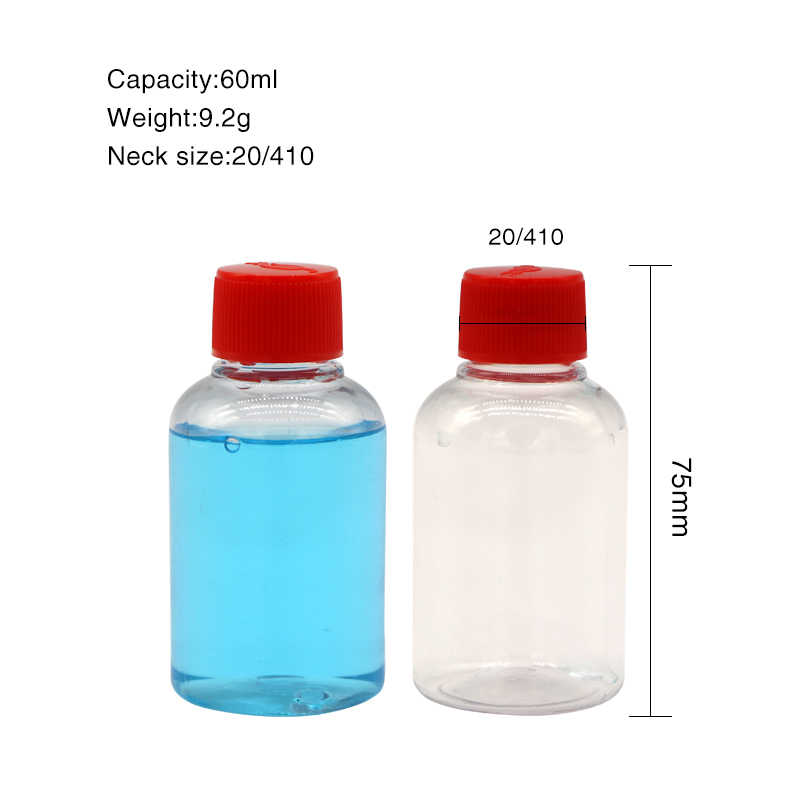

2oz PET Plastic Bottle Cosmetic Container Round Shape 60ml Transparent Bottle

Characteristics of PET bottle products

Neck detailing: Because the neck surface is injection-molded, the precision of neck detailing is usually much higher than other production processes such as extrusion blow molding (EBM) or normal blow molding (BM).

The neck size of PET bottles

PET plastic bottles usually use 18-410, 20-410, 24-410 or 28-410 industry standard neck processing, or use 18-415, 20-415, 24-415 and 28-415 higher neck processing.

By using these standard neck finishes, a wide variety of bottle caps such as plastic and aluminum threaded caps, flip caps, disc caps and nozzle caps are available, as well as a range of sprayers and pumps.

Weight of PET bottle

The weight of the package is determined during the injection molding of the prefab, so it cannot be changed easily. Manufacturers usually select the appropriate bottle weight and identify the specific characteristics needed in terms of top load, drop impact, and ease of filling, capping, and labeling of the product.

Label area

The label area is usually defined by height and width based on the circumference of the bottle.