China Cap and Cosmetic Packaging price - Manufacturers, Factory, Suppliers from China

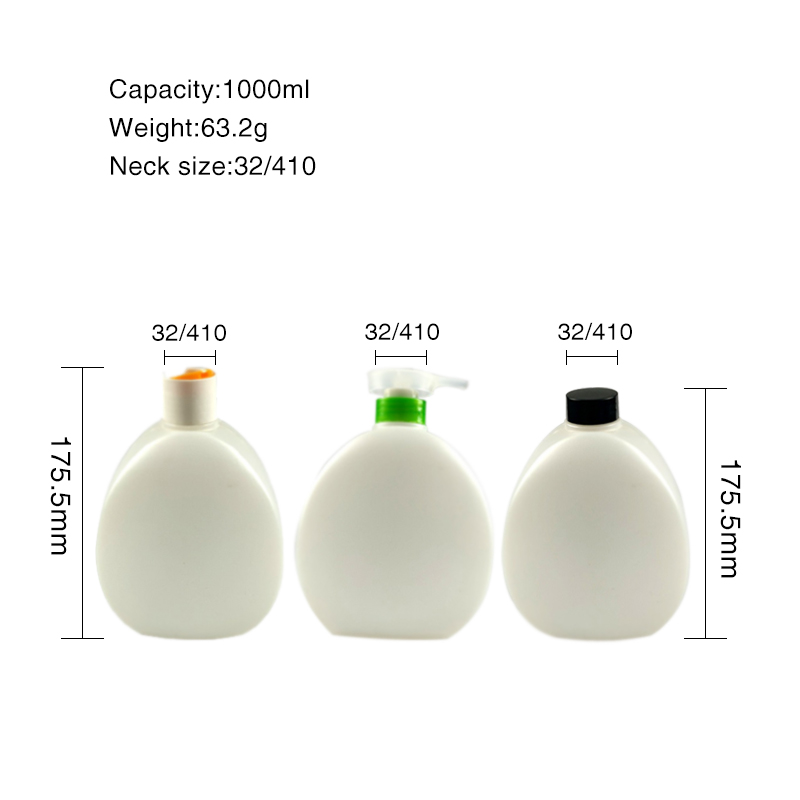

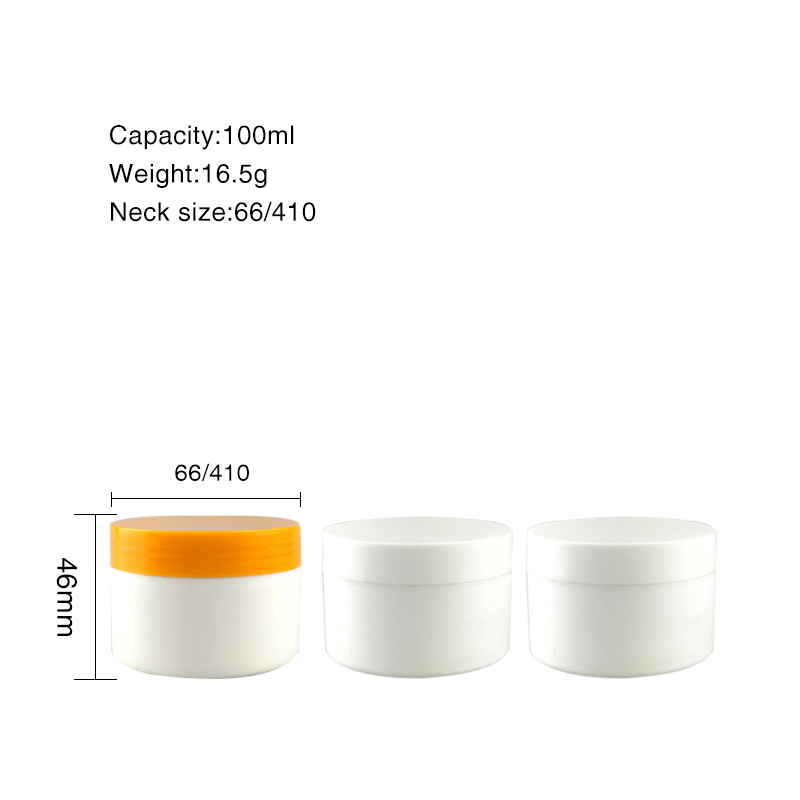

Plastic shampoo bottles are a must in the hair care industry. We specialize in the manufacture and export of high quality Plastic Shampoo Bottles which are essential for the packaging of hair care products at our plastic products factory. With more than 10 years of experience, we have become a trustworthy and reliable plastic shampoo bottle manufacturer. Our Shampoo Bottles are manufactured using high-quality raw materials to ensure their durability and strength. We use advanced injection molding techniques and state-of-the-art machinery to produce shampoo bottles of consistent quality, available in a variety of sizes and shapes to suit every customer's needs. We understand the importance of branding and marketing, which is why we provide our clients with customizable solutions. Our team of experts will work with you to create a custom design to showcase your brand and make your shampoo bottle stand out on the shelf. The quality of our products and our commitment to customer satisfaction have helped us build long-term relationships with our clients. We pride ourselves on being able to provide competitive pricing, prompt delivery and excellent customer service to all of our customers. If you are looking for durable, flexible and customizable high quality plastic shampoo bottles, please contact us. We are always ready to provide you with a tailor-made solution to meet your shampoo bottle needs. China Cap and Cosmetic Packaging price, Small Plastic Spray Bottles , Plastic Pump Bottle , Screw Cap For Medicine ,Packing Plastic . The company aims to continuously improve its products and services, provide competitive pricing, and maintain excellent customer relations. Their products have been exported to many countries worldwide and have gained a favorable reputation for their quality and affordability. The product will supply to all over the world, such as Europe, America, Australia,Lahore, Kuwait,Washington, Barcelona.Zhongshan Huangpu Guoyu Plastic Products Factory is a one-stop shop for all your plastic packaging needs. We specialize in manufacturing plastic bottles, caps, pumps and sprayers at competitive prices without compromising the quality of our products. With our state-of-the-art production facilities and experienced workforce, we can provide you with customized plastic packaging solutions to meet your specific requirements. We can provide you with a complete range of plastic packaging for a variety of industries, including cosmetics, cleaning solutions, and food and beverage packaging. At our factory we take quality very seriously and we source only the highest quality materials for our products. Our QC team conducts rigorous quality checks at every stage of the production process to ensure that every product that leaves our factory is of the highest standard. We are committed to providing our customers with a hassle-free experience from order placement to delivery. Our efficient logistics team ensures that your order is shipped on time and delivered in a timely manner. Our goal is to be your trusted partner for plastic packaging solutions. We work closely with our clients to understand their needs and provide custom solutions that meet those requirements. We look forward to working with you to provide quality plastic packaging products that exceed your expectations. Contact us today to discuss your requirements.