China Screw Cover and Screw Cap - China Manufacturers, Factory, Suppliers

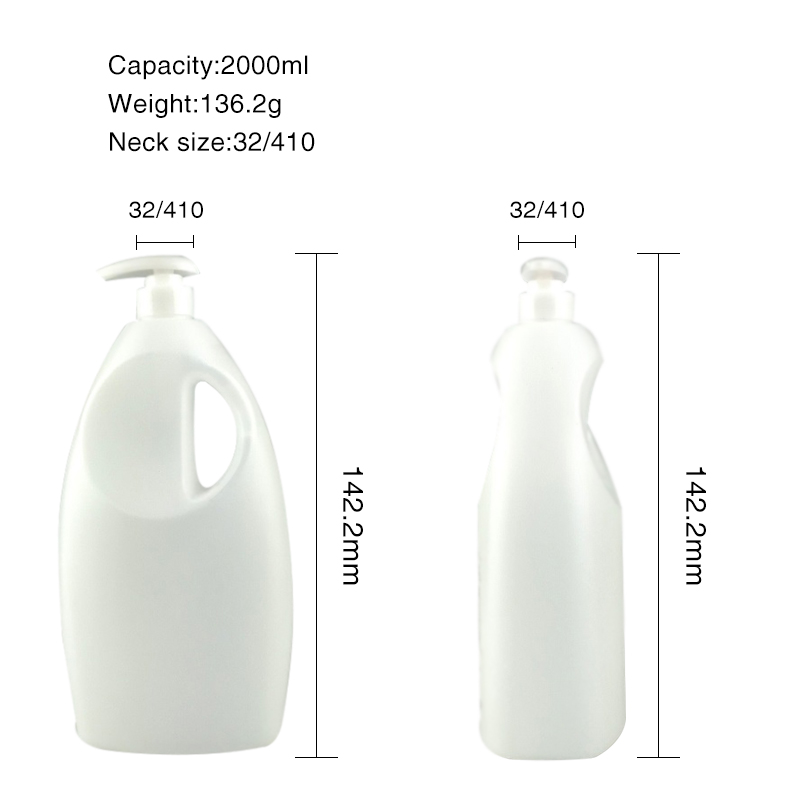

Plastic shampoo bottles are a must in the hair care industry. We specialize in the manufacture and export of high quality Plastic Shampoo Bottles which are essential for the packaging of hair care products at our plastic products factory. With more than 10 years of experience, we have become a trustworthy and reliable plastic shampoo bottle manufacturer. Our Shampoo Bottles are manufactured using high-quality raw materials to ensure their durability and strength. We use advanced injection molding techniques and state-of-the-art machinery to produce shampoo bottles of consistent quality, available in a variety of sizes and shapes to suit every customer's needs. We understand the importance of branding and marketing, which is why we provide our clients with customizable solutions. Our team of experts will work with you to create a custom design to showcase your brand and make your shampoo bottle stand out on the shelf. The quality of our products and our commitment to customer satisfaction have helped us build long-term relationships with our clients. We pride ourselves on being able to provide competitive pricing, prompt delivery and excellent customer service to all of our customers. If you are looking for durable, flexible and customizable high quality plastic shampoo bottles, please contact us. We are always ready to provide you with a tailor-made solution to meet your shampoo bottle needs. China Screw Cover and Screw Cap, Plastic Dispenser Bottles , Plastic Safe Cap , Disc Top Flip Cap ,Silver Disc Top Caps . So whether you're a beauty guru looking to simplify your routine, or someone who loves a quality hat, our disc tops are perfect for you. Easy to open and close, stylish designs and a variety of size options, you won't know your life without them! So go ahead and give your bottles the upgrade they deserve - you won't regret it. The product will supply to all over the world, such as Europe, America, Australia,South Africa, Kazakhstan,Australia, Belgium.One of the key benefits of using plastic PET bottles is their eco-friendliness. PET plastic is fully recyclable, which means that they can be repurposed into new products repeatedly. This makes them a sustainable choice for businesses looking to reduce their carbon footprint and promote environmental responsibility.