common lid - China Manufacturers, Factory, Suppliers

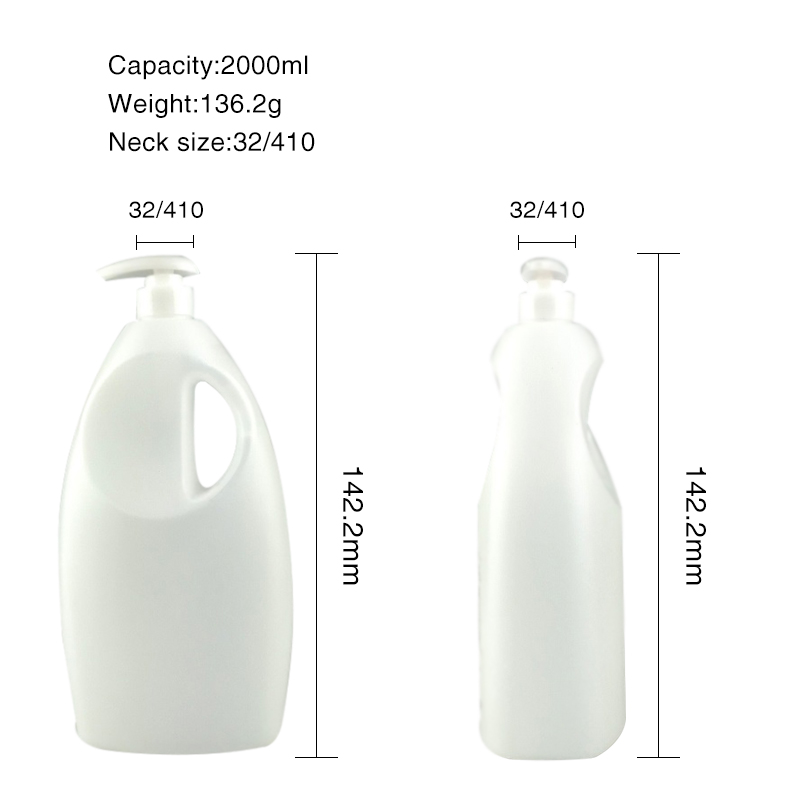

Plastic lotion pumps are an essential part of many personal care, cosmetic and healthcare products. These pumps provide an easy and hygienic way to precisely dispense lotions, creams and other viscous products. They are designed for ease of use, ensuring accurate dosing and preventing contamination. In our company, we specialize in the production of high-quality plastic lotion pumps that meet the needs of our customers. We use only the highest quality plastic materials for our pumps, ensuring they are durable, strong, and can withstand regular use without cracking or deforming over time. Our plastic lotion pumps are available in a variety of sizes to meet your specific requirements and can be customized to suit your branding needs. We offer different types of pumps including twist lock pumps, progressive cavity pumps and snap-on pumps that attach easily and securely to product containers. We understand the importance of precise dispensing when it comes to personal care and healthcare products, which is why our plastic lotion pumps are designed to provide precise dosage control with each pump. These pumps allow for easy and hygienic dispensing, preventing waste and contamination, which is critical for consumer-facing products. Whether you need plastic lotion pumps for your skincare, topical, or other personal care products, we have the expertise and technology to produce the high-quality products you need. Contact us today to learn more about our range of plastic lotion pumps and how they can add value to your product. common lid, Plastic Soap Dispenser Pump , Plastic Drop Cap , Disc Top Cap Suppliers ,Biodegradable Smug Jug . The company specializes in the design, development, and production of high-quality plastic products, including plastic containers, bottles, jars, caps, and closures. Their products are widely used in various industries, including cosmetics, food and beverage, household, and pharmaceuticals. The product will supply to all over the world, such as Europe, America, Australia,Slovak Republic, Malawi,Lisbon, Brisbane.The production process begins with the selection of high-quality raw materials, such as polyethylene terephthalate (PET) or high-density polyethylene (HDPE). These materials are then melted down and molded into the desired shape using specialized machines. The bottles are then subjected to quality control checks to ensure that they meet the required standards for strength, durability, and safety.